Energy production

Controlling the cost of the energy produced is a major challenge in order to remain competitive and attractive. Dynae provides its customers with its expertise to help them combine productivity and reliability for their equipment, as well as maintaining maintenance costs. Investigation techniques vary depending on the mode of power generation!

Turbo generator sts TGS

Beyond the signature under nominal conditions, the transient speed increase, excitation, coupling, load rise, temperature stabilisation, decoupling and speed reduction are recorded. The evolution of the vibratory and electrical signals acquired during all these critical phases makes it possible to characterise the behaviour and faults of the generator.

- Periodic vibratory signature of the turbo-generator sets

- Monitoring of relative and absolute vibrations

- Monitoring of bearing temperatures

- Electrical analysis of alternators with their exciter

- On-site balancing

Vibration and electrical diagnoses

A turbo alternator unit is a piece of equipment comprised of substantial electrical technology. The dual vibro-electric analysis is useful for carrying out a complete diagnosis of the mechanical and electromagnetic elements of the unit. This allows an overall diagnosis to be made:

- Review of electromechanical condition

- Diagnosis of mechanical and electrical faults

- Periodic analysis of motor currents

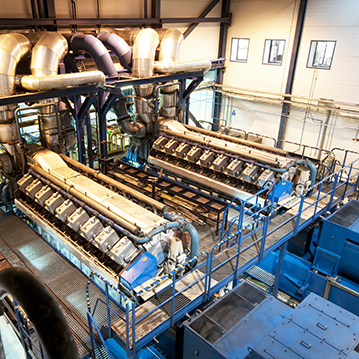

Thermal cogeneration plants

Unlike conventional rotating machines, fault diagnoses on a combustion engine requires other measures than vibrations: analysis of the lubricant, exhaust gas, temperatures, etc. However, the vibration analysis makes it possible to compare the levels with the standards and to identify certain faults.

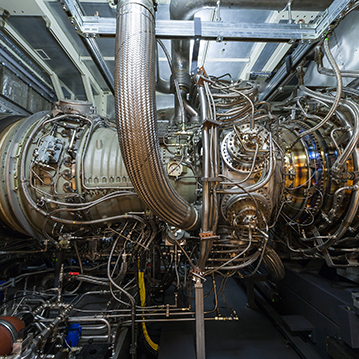

Combustion turbines

The diagnosis of turbo-alternator units driven by a combustion turbine requires a suitable operating mode: thermal expansions are rapid and significant, and a cold or hot start generally gives very different levels.

Hydroelectricity

Dynae is a leader in the field of diagnoses on hydroelectric generators. We have developed a dedicated operating method, measurement chains and "DynamX Hydro" software.

The specificity of this equipment and the way it operates require specific methodology and diagnoses.

The measurements relate to mechanical, electrical and hydraulic fault diagnosis, based on vibration, electrical, torque and pressure pulsation measurements.

Dynae is a leader in the field of diagnoses on hydroelectric generators. We have developed a dedicated operating method, measurement chains and "DynamX Hydro" software.

The specificity of this equipment and the way it operates require specific methodology and diagnoses.

The measurements relate to mechanical, electrical and hydraulic fault diagnosis, based on vibration, electrical, torque and pressure pulsation measurements.

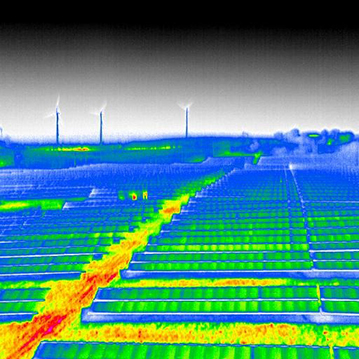

Photovoltaic panels

Dynae checks solar panel faults using aerial infrared thermography.

The on-board camera on a drone flies over the panels to detect faults. These are located on the drawing for an easy corrective response by maintenance teams.

Wind turbines

The fluctuations in torque and speed which the wind imposes on the wind turbine impact the entire shaft line, as well as the current produced, and in a permanent manner.

The detection of faults requires a particular methodology, in order to take into account these variations and to normalise the symptoms according to the conditions.

Software / Measurement solutions

Because each of the installations mentioned above is very specific, we have developed dedicated solutions:

- DynamXⓇ data acquisition and processing software

- Applications dedicated to DynamX Hydro hydraulic turbines

- Capturing fleeting disturbances with AdorecⓇ

- CTMOⓇ for easy signal acquisition

- DygivibⓇ smartphone application

- Dedicated TIR image acquisition system with drone