Setting up new utilities

Establishing new machines near homes or offices requires having good knowledge of their vibratory impact on the neighbourhood. It is necessary to study the decoupling of the machine, measure the mitigation of vibrations in the structures and this has to be done for each excitation frequency.

Acceptance test for new installations

When commissioning a refrigeration unit, an air treatment plant, or a boiler, it is important to perform a zero point. It makes it possible to decide on compliance with standards and verify that there are no disturbances near the neighbourhood.

The handing-over is also a zero point which will serve as a reference in case of drift over time.

Vibratory and electrical diagnoses

In case of malfunction or anomaly, Dynae performs a diagnosis to find the origin of the fault in order to decide how serious it is and recommend remedies. The analyses are adapted to the problem: vibration measurements, noise measurements, analysis of the resonance frequencies of the structure, electrical measurements, infrared thermography...

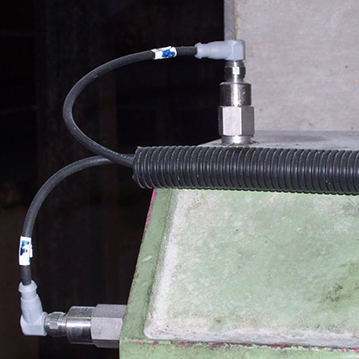

Vibration monitoring systems

Critical machines can be equipped with fixed temperature, current and vibration sensors to be notified in real time of a fault occurring.

Dynae advises, engineers, sets up and sets the parameters of the monitoring channels adapted to your requirements and budgets.

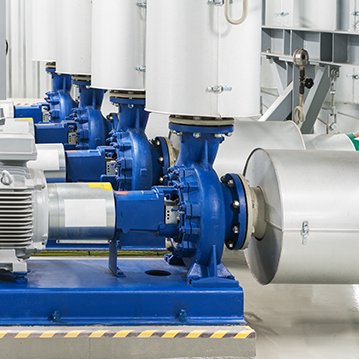

Conditional maintenance of equipment

The health check on a machine is carried out by a vibratory and sometimes electrical signature: this can detect possible faults to remedy them before the equipment failure. This is conditional maintenance.

In the tertiary sector, this concerns refrigeration units, emergency generator sets, fire pumps, air treatment plants, etc ...

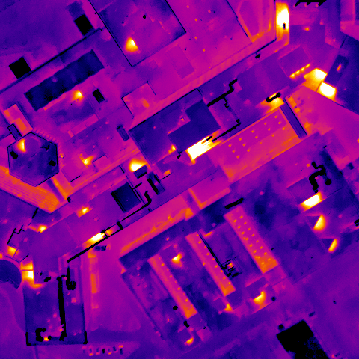

Thermographic analysis

Infrared thermography analysis is a major asset for the tertiary sector. Indeed, energy saving issues are at the heart of current building optimisation approaches.

Checking the energy efficiency of buildings, by assessing heat losses, before or after work is carried out (detecting leaks on walls, openings, roofs, heated floors) makes it possible to control energy expenditure, to perform the acceptance of the structures.

Similarly, the acceptance test and then the thermographic monitoring of the walls of boilers makes it possible in particular to detect leaks and heat losses and therefore greatly improve the output of the boilers, while helping to prioritise the work to be done.