Expert vibration survey of machines and structures with DynamX®

DynamX® consists of a basic version and fully compatible specialised additional modules.

The basic version is very complete and offers a wide range of main functions.

When it comes to the measurement and acquisition of signals, DynamX® drives National Instrument boards or OROS analysers. DynamX® records raw time signals, spectra, cascades and FRF. A wide range of signal processing tools allow you to post-process signals at will.

The data can also be downloaded from the routes collected with the CTMO®, or imported by many standard or proprietary file formats.

The signals database is extremely powerful for consulting and comparing graphs or for automating the calculation and editing of indicator tables.

All of these analysis tools enrich the automatic editing of the expert survey report in Word©

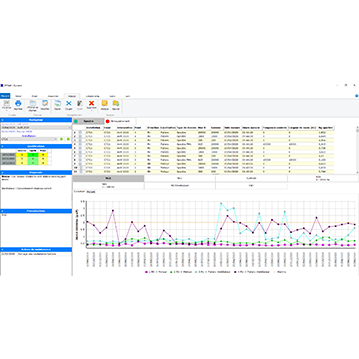

DynamX® Suivi: monitoring your fleet of machines

DynamX® Suivi is a variation of DynamX® dedicated to the vibration monitoring of rotating machines.

Optimal use is achieved with the CTMO® Mesure: Creation of routes, loading and unloading, editing trend curves with comparison to the thresholds.

The CTMO® transfers raw time signals to DynamX®, which allows automatic calculations of monitoring indicators to be performed, as well as being able to activate advanced processing for the diagnosis of complex faults.

The report editor restores the desired data in Word© format: measurement points, kinematics, operating conditions, evolution curves, spectra ... with analyses and recommendations.

This gives you a quick and summarised vibration diagnosis of your rotating machines, with the possibility of performing advanced processings for complex diagnoses.

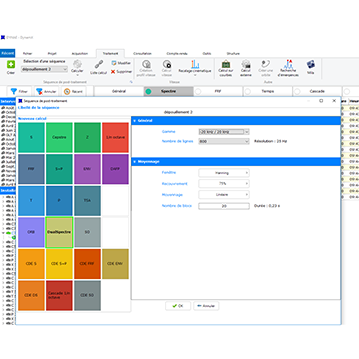

DynamX® – Expert module: signal processing dedicated to experts

The Expert module provides additional processing to the basic version, dedicated to the dynamic expert survey of your equipment: Analysis of orbits, dual-spectrum, synchronous analysis, demodulations, complex spectra...

It meets the more specific requirements of vibration analysis specialists to perform advanced dynamic measurements and analyses: rotating machine experts, manufacturers, consultants.

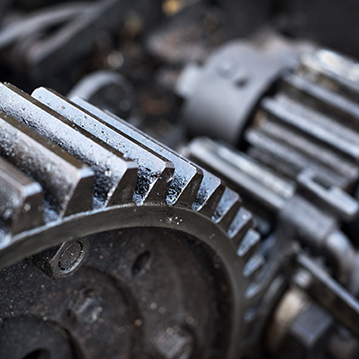

DynamX® – Gear module: advanced diagnoses for gear reducers and multipliers

The DynamX® Gear Module is an interactive tool dedicated to advanced gear diagnoses.

The module identifies meshing frequencies and extracts amplitude and frequency modulation functions from angular resampling of signals.

An interactive tool proposes to direct the analysis by choosing the harmonics and the number of sidebands of the meshing frequency to be taken into consideration.

The polar views give an image of the forces at each passage of the teeth, with shocks and modulations being highlighted.

DynamX® – Structure module: dynamic analysis of structures

The DynamX® structure module is an integrated tool for measuring transfer functions, calculating real deformations (RDS), operational deformations (ODS) and time deformations (TDS).

It is particularly effective in dealing with the case of rotating machines: it allows a quick comparison between the real and operational deformations in order to determine if there is a structural resonance.

Coupled with the CTMO®Structure for taking measurements, it is a very high-performance field measurement tool in difficult conditions: dust, humidity, access. The fact that it is battery operated gives it considerable autonomy for measurements.

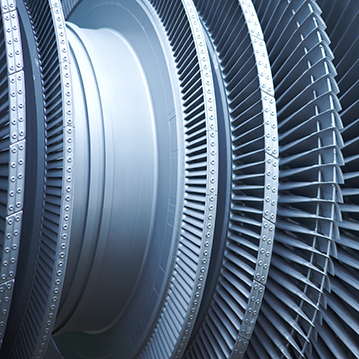

DynamX® – Turbomachinery module : for advanced vibration diagnoses of machines on plain bearings

This module offers tools dedicated to monitoring the start-up and shutdown phases required for the second-level vibration signature of a turbomachine: order tracking by angular sampling, Bode and Nyquist diagrams, phase monitoring.

Synchronous measurement with accelerometers and proximity probes makes it possible to plot the relative and absolute orbits of the shaft line on the same representation.