Petrochemicals - Chemicals

The dangerous nature of the fluids in the lines means that the reliability of the equipment must be reinforced as much as possible. Dynae therefore brings all its know-how to these industries, both on rotating machines and on piping and static equipment, to enable them to produce without any breakdowns and completely safely.

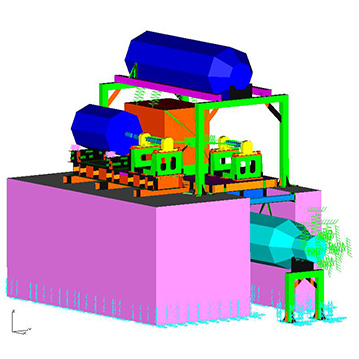

Dynamic calculation for thr layout of new equipment

The objective is to ensure that the new or modified installation will not encounter any vibration problems on start-up: the critical frequencies of shafts as well as the natural frequencies of the structure (frame, support, etc.) must be kept away from exciting frequencies. The amplification factor at the passage of critical frequencies must meet PLC requirements.

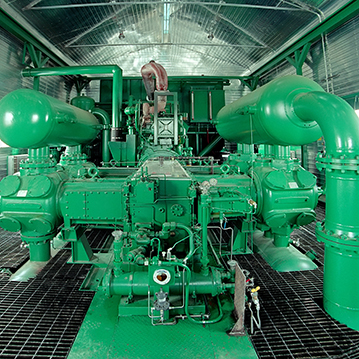

Handig-over of facilities

During commissioning or after a general service, it is necessary to check not only the absence of mechanical or electromechanical faults, but also the absence of structural faults inducing resonance problems. Compliance with PLCs and engineering guides is also validated.

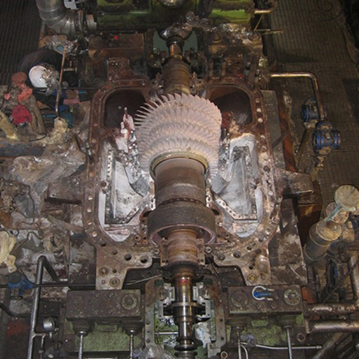

Diagnosis of rotating machinery faults

In the event of a high vibration alarm or indeed a malfunction, the purpose of the vibration diagnosis is to identify the cause of the fault, to judge how serious it is and to recommend corrective actions. The measurement programme is adapted to the problem each time.

This diagnosis provides the right recommendations for solving the problem and ensuring that production is maintained.

Diagnosis of static equipment and piping

Pipe vibrations, cracks ... can come from an abnormal mechanical or pulsating excitation, or from a problem with the support of a balloon or a pipe. It is therefore all about identifying the source of excitation on the one hand and determining whether to eliminate it or act on the response of the structure.

The health check on critical equipment

The vibratory and electrical assessment before/after a general service makes it possible to target maintenance actions and to take delivery of the machine after repair work. Electrical analysis is complementary to vibration analysis and makes it possible to decide on the presence of electromagnetic faults or faults inducing torque fluctuations.

Monitoring of furnaces and refrigeration units by infrared thermography

The good behaviour of refractories and thermal insulators is very important to plan work during unit shutdowns. Regular monitoring will make it possible to obtain real indicators on their condition and thus plan maintenance operations without any surprises when opening them.