Vibration and manufacturing faults diagnoses

Hot or cold rolling is an operation which involves very significant static and dynamic forces. The slightest fault can cause breakages, vibrations or manufacturing faults such as faceting of the sheets.

Various analyses are carried out depending on the problem to analyse the dynamic behaviour of a cage and decide on the origin of a fault:

- Vibration signature of cages and controls

- Analysis of dynamic torque fluctuations on the shaft lines

- Modal analysis of rolling mill stands

- Analysis of start/stop phases

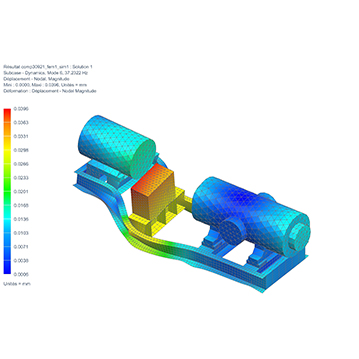

Dynamic study of machine layout

Setting up a new machine may require a dynamic study to avoid any problems during commissioning:

- Eigen frequencies and structural resonance

- Dynamic calculation of the host structure

- Qualification of the structure by measurements

- Torsional calculation of shaft lines

An acceptance test from installation to commissioning will validate the suitability of the structure for the calculations.

Specifics structural study

Vibration problems do not only come from kinematic chains and may require specific analyses:

- Analysis of structural vibrations: Cowpers, blast furnaces, chimneys, cranes and travelling cranes

- Diagnosis of pulsating vibrations: acoustic or flow phenomena

- Verification of anchorages and cracks in blocks

- Correction of resonance phenomena by finite element calculations

- Stress analysis in structures

Genset diagnoses

We step in to carry out a health check of all types of equipment: Pelton, Francis, Kaplan.

The measurements are carried out in accordance with 10816-5 and 7919-5 standards. They relate to the diagnosis of mechanical, electrical and hydraulic faults, using vibration and electrical measurements and sometimes torque and pressure pulsation measurements.

The measurements are carried out over the turbine’s entire operating range: no-load not excited, excited, quarter load, half load, full load.

Transient phases are also recorded.

Software / Measurement solutions

Dynae has developed hardware and software solutions which perfectly meet the requirements and constraints specific to iron & steel sites, in order to facilitate measurements and data analysis

- DynamX® data acquisition and processing software

- Capture of transient phenomena with Adorec®

- CTMO® for easy signal acquisition

- Dygivib ® Smartphone application