Pharmaceuticals - Cosmetics

We know the requirements of this sector in terms of cleanliness, quality, traceability, equipment qualification. Combined with the strength of our presence in terms of proximity, our advantage is that we master the requirements of this sector, as well as the specific features of its very particular equipment.

Conditional maintenance of equipment

Monitoring by means of vibratory analysis, infrared thermography, electrical analysis, oil analysis, US ... allows to monitor the health status of the fleet of machines to avoid failures and prepare maintenance operations in advance.

This is particularly useful in this industry, where the batches produced can account for significant amounts.

Any production stoppage may therefore be dramatic, with both economic and strategic challenges.

The health checks on utilities (Air treatment units ATU, refrigeration units, compressors, vacuum pumps ...) and means of production (centrifuges, autoclaves, tumblers ...) therefore provide unparalleled visibility as to the state of this equipment.

In addition to the benefits themselves, Dynae carries out consulting and training work to support its customers in optimising predictive maintenance, dedicated to their equipment

Vibratory and electrical diagnosis

This diagnosis is the basis of conditional maintenance tools and aims at an electromechanical health check to determine the origin of both mechanical and electric faults.

The measurements are performed periodically, or when a fault is proven and that the source and solution should be found.

Balancing and diagnosis of structure problems (resonance, cracking, chassis sizing or insulating pads) provide a significant extension of the life of ATU for example.

Turnkey protection and motoring solutions

What is the safest way to monitor a vital installation for the process?

Installation of an on-line monitoring system.

After performing a preliminary study to define the characteristics and architecture, it is possible to choose the solution best adapted to the challenges and context.

Dynae can then go further by offering you a turnkey solution which includes supplying and installing the hardware, setting the system’s parameters and the acceptance phase. We will then be able to train you how to use this system and monitor remote installations (remote diagnosis).

In addition, the systems we propose are completely open to Big-data and artificial intelligence solutions which we can work together on.

Diagnosis and Solutions for Sensitive Equipment

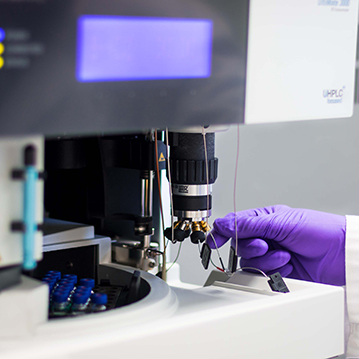

Some sensitive equipment (microscopes, chromatographers, precision weighing ...) can be disrupted by external vibratory sources, preventing an adjustment, a precision measure-ment...

It is therefore a question of carrying out a vibration impact and transfer study to find the origin and to propose solutions such as the reinforcement or modification of vibration insulation, decoupling solutions, the removal of the source…