Diagnosis of on-board equipment

Ships must be able to rely on a large number of critical navigation and safety equipment. Their vibratory signature makes it possible to decide on their state of health, to diagnose faults and to recommend corrective operations.

Analysis of propulsion lines

Vibration measurements on motors, reducers, bearings and stern tubes are very useful for checking the condition and proper operation of the production line: runout, edging, imbalance, coupling fault, bearing clearance, etc. Torque measurements can be performed to measure the torque fluctuations of the shaft.

In dry conditions, the bearing alignment is carried out by laser, or in long range with theodolite.

Vibratory and acoustic nuisance

Due to the multiple sources of excitation present and which change with the speed, as well as the relative flexibility of the hulls and decks, a vibratory and acoustic study of the cabins is sometimes necessary to identify the resonances, search for propagation paths, and propose solutions to ensure comfort in accordance with standards.

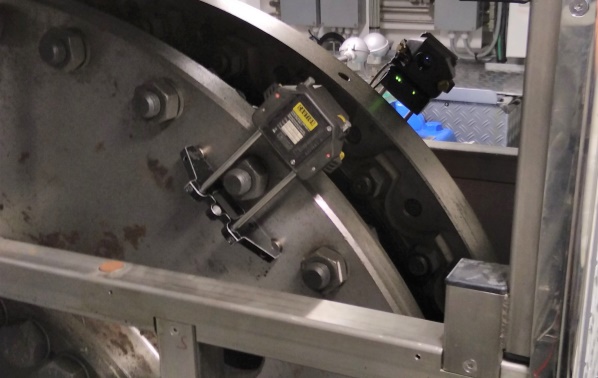

Alignement

The correct alignment of a propulsion line requires specific tools and know-how. When dry, we will check the correct alignment from the landing chair, the stern tube, to the engine.

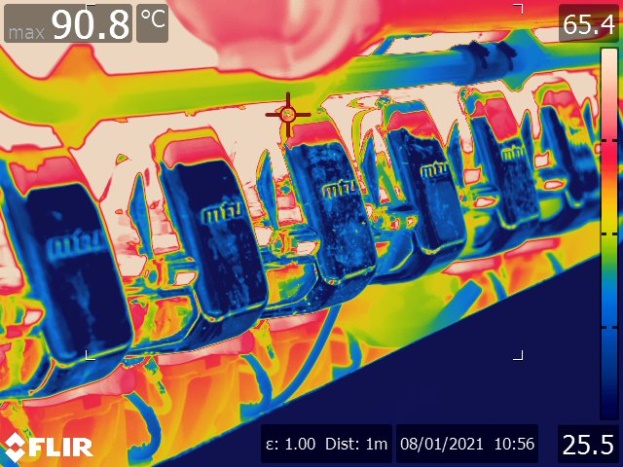

Infrared thermography

Thermography is particularly useful for checking the absence of hot spots on electrical cabinets, due to the mechanical stresses to which they are subjected, and the importance of the fire risk.

It will also be possible to check the good condition of the heat insulators and the temperatures of the exhausts and cylinder heads.