The analysis of vibratory and electrical signals measured on rotating machines is a very powerful tool for establishing a comprehensive, overall diagnosis. Comprehensive, as we will try to go back to the origin of the fault and observe its effects, without necessarily having access to a history.

Overall, as it integrates the mechanical part of the entire shaft line, the motor or alternator with its electrical circuit, and the surrounding structure.

Diagnosis of rotating machines

Its purpose is to take a decision on the state of the equipment, to assess how serious the faults detected are, to determine their origin and to recommend targeted corrective actions.

Vibration analysis is the main investigative tool used by experts. The vibration measurement is carried out on the bearings of the shaft line. For machines on plain bearings, it is recommended to measure the relative vibrations of the shaft in its bearings, using proximity probes. The electrical signature of the motor or alternator current also gives an image of torque fluctuations. A specific test programme is established depending on the context. It can include the recording of the starting and stopping phases, as well as the measurements of the natural frequencies of the shafts and bearings.

We perform SOS diagnoses when a problem occurs: alarm, abnormal noise, etc. A vibration assessment before / after stopping maintenance is recommended for strategic machines.

Our advantage: combined vibration-electric-structure analysis

Dynamic analysis of structures

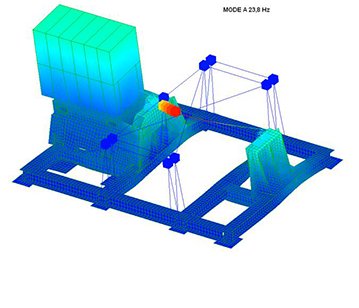

It purpose is to find out about the vibratory behaviour of the structure in response to dynamic excitation forces. This makes it possible to avoid a resonance problem, to size a shaft line, a machine frame or a mechanical part.

Dynamic analysis is also very useful for predicting and correcting pipe vibrations in units.

Modelling by finite elements makes it possible to determine the eigen modes (modal analysis) as well as the vibratory response to a dynamic force (response calculation). The measurement of transfer functions and modal deformations on site is carried out using an impact hammer.

Our advantage: combining measurements and the simulation

Electrical expert surveys

The diagnosis of electrical equipment concerns all installations, from the delivery station to the loads: network, transformers, drives, motors and generators

Its purpose is to carry out an audit, an acceptance test, a follow-up or a fault diagnosis of the network or the consumers.

It is based on a balance of power, associated with the analysis of the shape of the signals, as well as insulation measurements. The AdoRec® system is dedicated to capturing fleeting disturbances.

These measurements make it possible to detect network faults, regulation problems, as well as electromagnetic faults in rotating machines.

For turbo-generator sets, a specific vibratory and electrical test programme is recommended to record their electromechanical behaviour in all stages of speed increase, coupling and load variations.

Our advantage: electrotechnical and vibration expertise